Electromagnetic Pump (EMP) Systems

Overview

Electromagnetic pump systems (EMPs) are molten metal pump systems without mechanical parts. They are designed for efficient forced furnace circulation, molten metal transfer and charging of light-gauge scrap and alloy additions in applications for continuous or dry-hearth operations, in static or tilting furnaces and single-chamber or multi-chamber furnaces.

Pyrotek Offerings

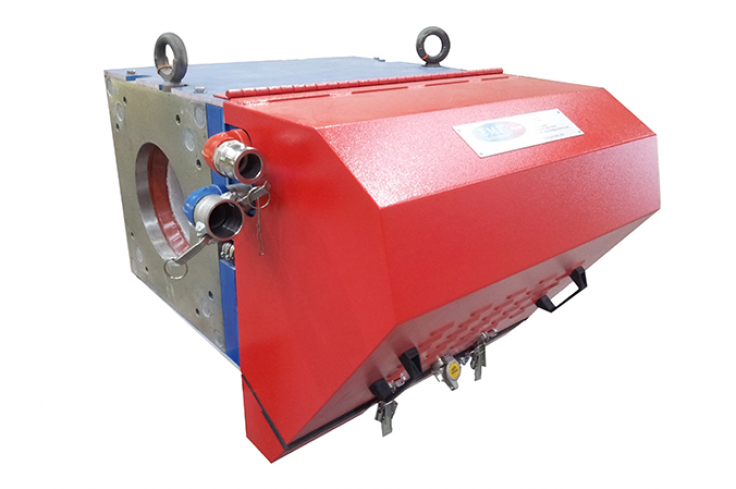

Pyrotek EMP systems are made up of several components that create an efficient and effective molten metal pumping system. At the heart of the system is the EMP pump which exerts electromagnetic forces on molten aluminium to propel it through the system and into the furnace it is connected to. Electromagnetic pumps are compact and connected inline to tubing with no moving parts.

The next integral part of the EMP system is the EMP chargewell. These chargewells are custom refractory lined vessels which produce a downward, swirling current of aluminium that has very low turbulence ideal for scrap or alloy adition submergence. Mounted on top of the chargewell is a chargewell (top hat) burner. The burner is used for preheating and raising temperature during start-up or maintaining temperature between melt cycles of the chargewell refractories and connecting tubing, to the operating temperatures so that aluminium does not freeze in the system.

EMP systems incorporate EMP water pump sets, which cool the pump at a maintained temperature through an advanced water cooling system.

The system status is controlled, monitored and data captured in real-time operation utilizing probes, sensors safety circuits and instrumentation via process logic control integrated into Pyrotek's EMP control panel system.

- Having no mechanical pumping parts reduces required maintenance and consumable part costs

- Improve furnace efficiency, furnace cycle time and melt quality, reduced energy (natural gas) consumption

- Minimal disturbance of bath surface reduces oxide generation

- Ensure excellent chemical and temperature homogeneity

- Ability to circulate, transfer and charge scrap in one system

- Electromagnetic Pumps (EMP)

- EMP Chargewells

- EMP Chargewell (Top Hat) Burners

- EMP Water Pump Sets

- EMP Automated Tap Out and Overflow Transfer

- Control Systems